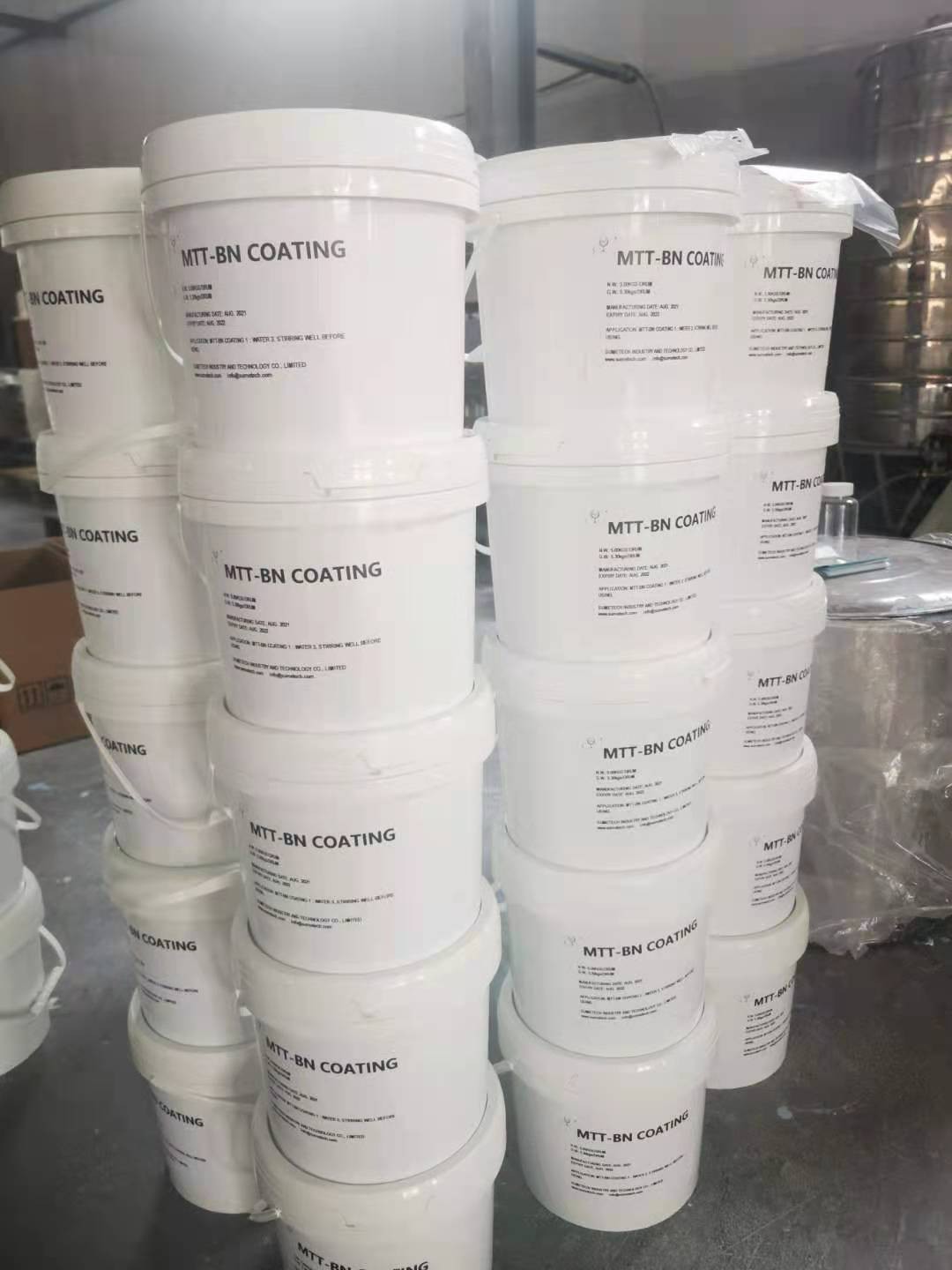

Description

Boron Nitride Coating

Hexagonal boron nitride suspension exhibits high thermal conductivity. It is not impregnated with molten metals and can be applied directly to surfaces that require protection, even when those surfaces are already hot. This material maintains its consistency at elevated temperatures and is inert to metals, glass, and molten salts.

Boron nitride coating possesses unique properties, making it an ideal lubricant for high-temperature components and tools. It serves as a release agent and an effective coating for extremely hot materials. Boron nitride remains effective at temperatures up to 800°C in air and 1950°C in inert gas, establishing it as an excellent dry lubricant.

Application of Boron Nitride Coating

High-Temperature Lubricant (1950 °C)

High-Temperature Release Agent

Protective Coating for Metals, Ceramics, Ceramic Fibers, and Graphite

Facilitates the casting of molten metals, including aluminum, magnesium, zinc, and lead.

Facilitates the sliding of press tools at extremely high temperatures.

Boron nitride (BN) acts as a semiconductor at elevated temperatures and serves as an insulator at room temperature.

How to Use Boron Nitride Coating

1. Diluted with distilled water before use, with different objects, requirements of dilution ratio are also different. Dilution ratio: BN:water=1:1-6, customers can be adjusted according to the requirement.

2. After dilution, mixing evenly, clean the protected material surface. With sponge (brush, spray gun) will dilute boron nitride coating coated on the material surface.

3. After finishing the coating, drying under 300° C, can be used after drying.

Note: The coating should be uniform, do not make the BN in surface aggregation, which do not apply too thick.

Advantage Boron Nitride Coating

1. Good high temperature stability, and non sticking molten metal.

2. Non-toxic, no smell, no pollution.

3. Special formula, water solubility, completely soluble in water, easy to use.

4. High temperature resistance, high lubricity, corrosion resistance.

5. Can be coated on the hot or cold surface of protected material, after drying can be used dry soft cloth or paper processing, smoothing and polishing.

BN boron nitride coating, aluminum castings coating and die casting release coatings for casting materials