Description

Packing: 5 kg/bag, 1000 kg/ bag

Storage: store the Granulated Flux in a sealed bag to avoid moisture.

Application: electrolytic aluminum plant, remelting aluminum plant and waste aluminum remelting plant

Main functions: removal of sodium, calcium, lithium and non-metallic inclusions (oxides, carbides and borides)

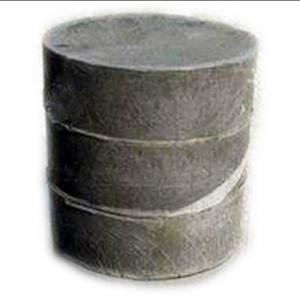

Appearance: white, light yellow and yellow and light gray irregular cube particles.

Method of use: aluminum liquid temperature 740-760 ℃. Spray evenly into the bottom of the molten aluminum with an electric duster, or in a mechanical or electromagnetic pump vortex well with a bag or jet head injection.

Chemical composition phase: KMgCl3

MgCl2 60%, KCl 40%, NaCl 0%, water insoluble matter ≤1.0%, H2O ≤0.5%, melting point ≤488℃

The refining agent reaction is rapid, which can effectively remove from liquid aluminum and hydrogen furnace refractory lining of lithium, sodium, and calcium, for magnesia aluminium refining, can make the sodium content is less than 1 PPM.

The removal of alkali and nonmetallic inclusions by refining can be improved

l It is helpful to improve the delivery speed and prolong the service life of the mould when extruding the profile

l Reduce the edge crack of high magnesium alloy during rolling

l Reduce the number of stops for continuous casting and rolling

Product advantages:

l Smokeless and odorless

l Reduce the use of chlorine gas

l The particle shape is designed to spray 0.8-3.15 mm

l Zero emissions of fluoride, hydrogen chloride and dust are below the emission standards set by the United States environment agency

l Harmless compound

l Low melting point, ≤488℃, contributes to rapid and uniform dispersion

l Lower hygroscopicity than magnesium chloride powder

l Low usage, 1-2 kg per ton of aluminum recommended usage

l Keep furnace, flow launder, line degasser and casting mouth free from silt and slag accumulation

l Reduce the burning loss of aluminum, reduce the burning loss of 0.5% per ton of aluminum, the cost per ton of aluminum savings of about $10